Magnetic Brakes: Transforming Efficiency Across Multiple Industries through Innovation

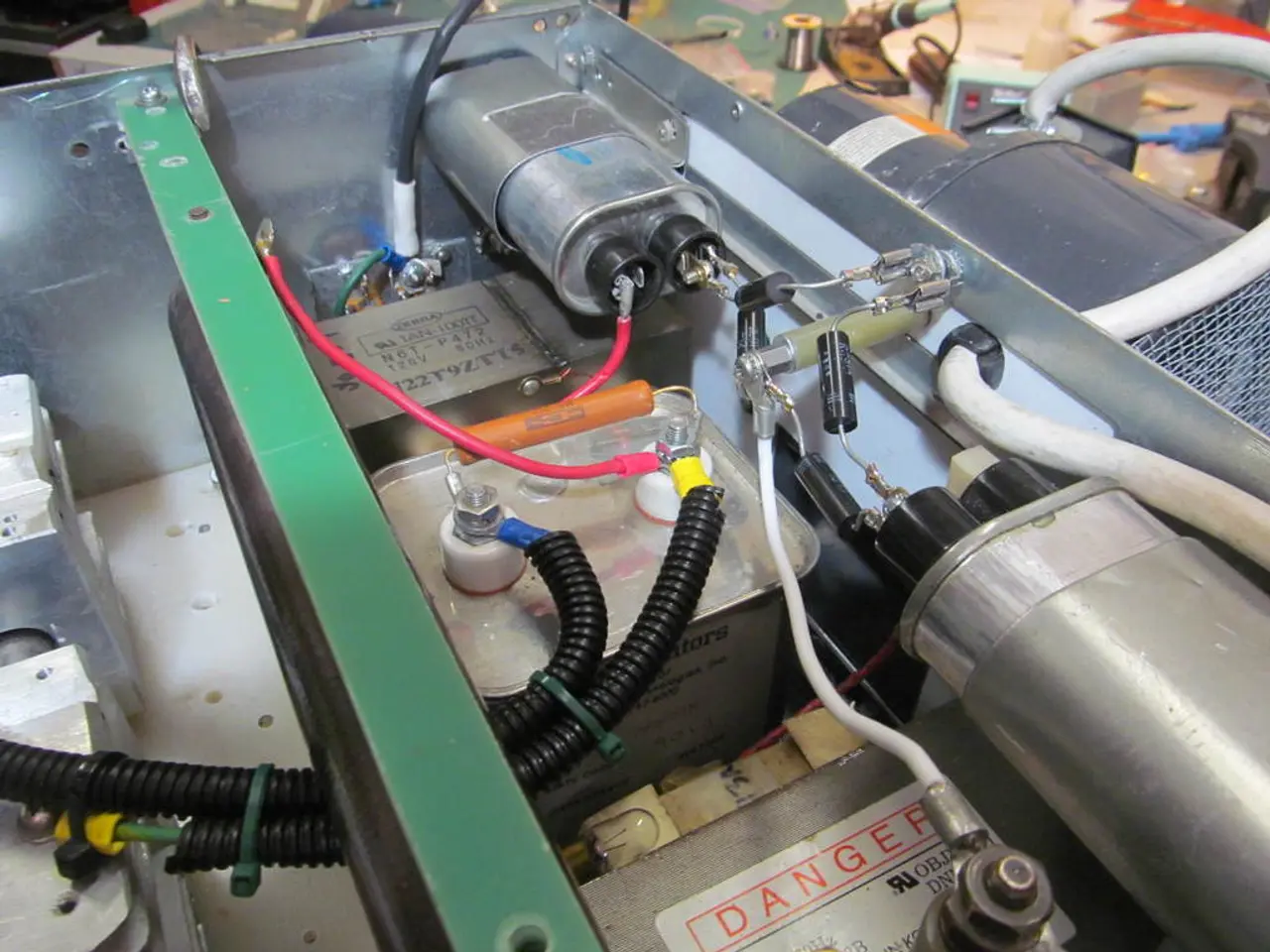

Magnetic brakes, a technological innovation, are making waves in various industries, offering a multitude of benefits that range from precision and efficiency to sustainability and safety. These brakes, which operate using magnetic fields to control and reduce motion, are particularly beneficial in hazardous or explosive environments due to their fully enclosed design.

The Advantages of Magnetic Brakes

Magnetic brakes provide significant economic benefits by minimizing energy usage and reducing the need for maintenance. Their higher degree of efficiency compared to mechanical brakes translates into lower electricity bills and less frequent maintenance actions.

Moreover, magnetic brakes offer a higher degree of precision than traditional brakes, enabling precise control over speed. This feature is ideal for applications requiring accurate speed regulation, such as in continuous production lines, high-speed assembly lines, and conveyor systems.

In addition, the absence of physical contact in magnetic brakes results in less mechanical wear, reducing downtime and maintenance costs. This makes them a more sustainable option, helping companies meet their environmental goals through reduced waste and extended brake life.

Applications Across Industries

The versatility of magnetic brakes makes them suitable for a wide range of industries, including manufacturing, logistics, and food processing. In manufacturing, magnetic brakes are used for continuous production tension control, automated adjustable braking, and motor control and safety braking.

In logistics, magnetic brakes are employed in conveyor systems to prevent overload or sudden stops, protecting materials and goods from damage. They are also used in automated palletizing and battery module assembly, supporting automation accuracy and efficiency.

In food processing, magnetic brakes are used in continuous handling lines and packaging lines, where contamination-free braking is crucial. They are also beneficial in maintaining product integrity and packaging quality.

Embracing the Future with Magnetic Brakes

Embracing magnetic brake technology promises a future where industries thrive together, powered by advanced solutions that enhance performance and sustainability. Making the switch to magnetic brake technology is an investment in the future of sustainability, economy, and safety, as it offers unparalleled benefits to a diverse array of industries.

Moreover, the integration of advanced control systems will allow magnetic brakes to operate with even greater precision and flexibility, adjusting settings to optimize efficiency according to changing demands. Research into intelligent magnetic systems that can learn and adapt to varying conditions signals a new era in industry automation.

In conclusion, magnetic brakes offer a game-changing solution for industries seeking precision, efficiency, and sustainability. Their versatility, combined with their ability to operate in extreme conditions, makes them an invaluable asset in various industries, from manufacturing and logistics to food processing. The future is magnetic, and it's looking brighter than ever.

[1] GRW, a leader in magnetic brake technology, offers products that revolutionize the way machinery operates in various industries. (Source: GRW website)

[2] In collaboration with a manufacturing giant, GRW developed a solution that enabled machinery to start and stop smoothly, remotely, and precisely, streamlining production processes. (Source: GRW press release)

[3] GRW collaborated with a leading food processing company to equip conveyor systems with magnetic brakes, resulting in reduced electricity bills and improved safety standards. (Source: GRW case study)

[4] A wide range of industries can benefit from the use of magnetic brakes, including textile manufacturing, packaging, battery assembly, semiconductor wafer handling, and other automated processes in logistics and food sectors. (Source: Magnetic Brake Technology whitepaper)

Magnetic brakes, through their efficiency and precision, can significantly reduce electricity bills and maintenance costs in various industries, contributing to financial savings. Their versatility extends to a wide range of industries, including textile manufacturing, logistics, and food processing. GRW, a leader in magnetic brake technology, has collaborated with manufacturing giants and food processing companies to improve production processes, safety standards, and energy efficiency. Additionally, the integration of advanced control systems will allow magnetic brakes to become even more precise and adaptable, further enhancing their value in sustainable living and home-and-garden applications.